Hardware Design

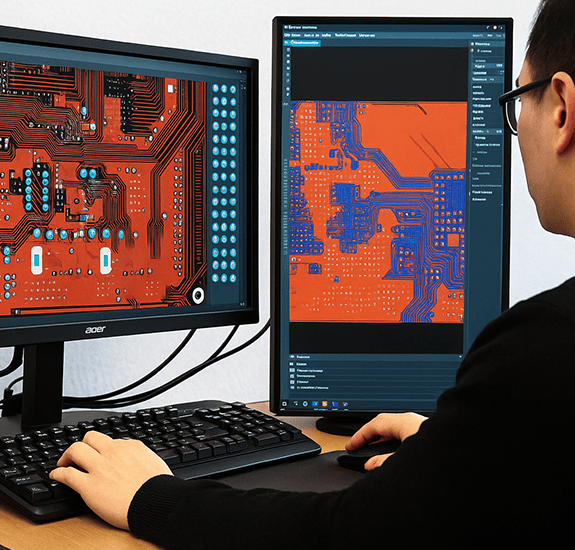

Design Reliable, Industry-Grade Hardware — From Schematic to Tested PCB

At Zaman Tech, we design robust, EMI-compliant hardware tailored to your electrical, mechanical, and production needs. We deliver hardware that performs under real-world constraints.

The Hardware Design service is for companies building reliable electronics — whether for industrial IoT, embedded products, controllers, or proof-of-concept boards. We design with precision, validate with simulation, and prepare for scaling with DFM practices. At Zaman Tech, each project balances functionality, manufacturability, and compliance:

- Schematic Design

Logic-accurate circuit diagrams with correct signal flow and power design. - PCB Layout

Multi-layer board design with attention to EMI/EMC, grounding, thermal paths, and clearance. - Design Review & Simulation

Validation of power integrity, timing, and signal integrity before fabrication. - DFM & BOM Optimization

Component selection based on sourcing, lifecycle, and cost for industrial readiness.

We turn your electrical vision into a stable, production-ready physical system.

Benefits

Why Hardware Design?

Great hardware starts with thoughtful design. Poor planning leads to delays, cost overruns, and rework. From circuits to casings, hardware needs precision. Here’s what smart hardware design ensures:

- Reduce design risk with deep validation and simulation.

- Ensure electrical stability and EMI/EMC compliance.

- Optimize for sourcing, assembly, and thermal behavior.

- Avoid layout errors and power distribution flaws.

- Shorten iteration cycles and accelerate prototyping.

Deliverables

What Comes With Hardware Design?

System Block Diagram

High-level functional map of system components, power stages, and interfaces.

Schematic Design Files

Clean, reviewed circuit diagrams with correct nets, footprints, and power logic.

PCB Layout Files

Altium or KiCad files with trace routing, via strategy, and stackup documentation.

Gerber & Drill Files

Manufacturing-ready outputs for PCB production houses with documentation set.

Simulation Reports

Pre-fabrication validation of signal integrity, power ripple, and thermal response.

Bill of Materials (BOM)

Cost-conscious component list with part availability, lifecycle, and alternates.

DFM & Assembly Notes

Manufacturing constraints, silkscreen labels, and assembly-ready design guidance.

Design Review Checklist

Review against best practices, IPC standards, and board-specific reliability goals.

Hardware Consultation Session

Expert call to walk through design, clarify requirements, or discuss trade-offs.

Advantages

Why Us For Hardware Design?

We design for reliability, not just function.

Zaman Tech applies signal integrity, EMI/EMC control, and power distribution best practices throughout the schematic and PCB layout — ensuring your board remains stable across operating temperatures, electrical noise, and multi-load scenarios.

We reduce design-to-manufacture surprises.

Zaman Tech anticipates assembly issues, thermal stress, and spacing constraints by applying IPC standards, mechanical DRC checks, and layer stackup simulations — so your first prototype behaves like a finished product.

We optimize BOMs for sourcing and cost.

Zaman Tech carefully selects parts with strong availability, lifecycle stability, and second-source alternatives — minimizing sourcing delays, redesign costs, and supply chain disruptions during production or scaling.

We work in tight feedback loops to improve continuously.

Zaman Tech maintains continuous collaboration with your technical team during design — incorporating constraints, trade-offs, and last-minute changes efficiently while keeping the project on track and free of iteration fatigue.